Additional information

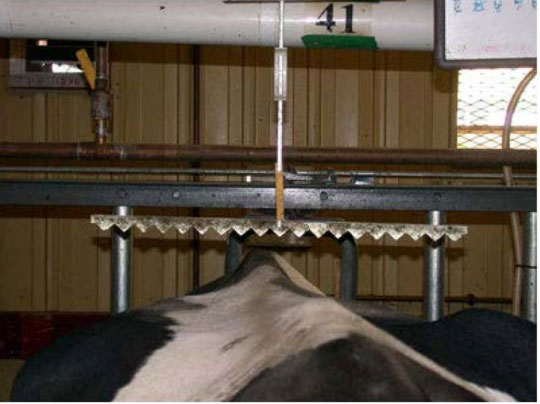

The electric “cow trainer” is used in tie-stall housing systems in which cows are tethered by their necks to individual stalls. Typically, the head of the stall will face an alley where feed and water are accessible to the cow. At the rear of the stall is a gutter which is intended to catch waste eliminated by the cow. To prevent the cow from eliminating in the space of the stall, milk producers install an electrified metal bar above a cow’s back that will deliver an electric shock when she hunches to defecate. Contact with the bar forces her to move backwards into the “proper” position before defecating.

The veterinarian, Terry Whiting, explains the use-case for the “cow trainer” as follows:

When standing with the head and neck in the manger, body position allowed for manure to fall on the lying area of the cow not in the gutter as the building was designed. A cow trainer is a horizontal electrified metal bar that is placed such that when a cow arches her back in positioning for excrement elimination, her dorsal spine at the shoulders will come into contact with the electrified bar. The resultant experience of electrical current flow through her body will result in the cow taking a step backward, away from the electrical contact and increase the probability of eliminating in the gutter. In North America, cow trainers were widely adopted in tie stall systems… [and] remains an accepted practice in Canada.[1]

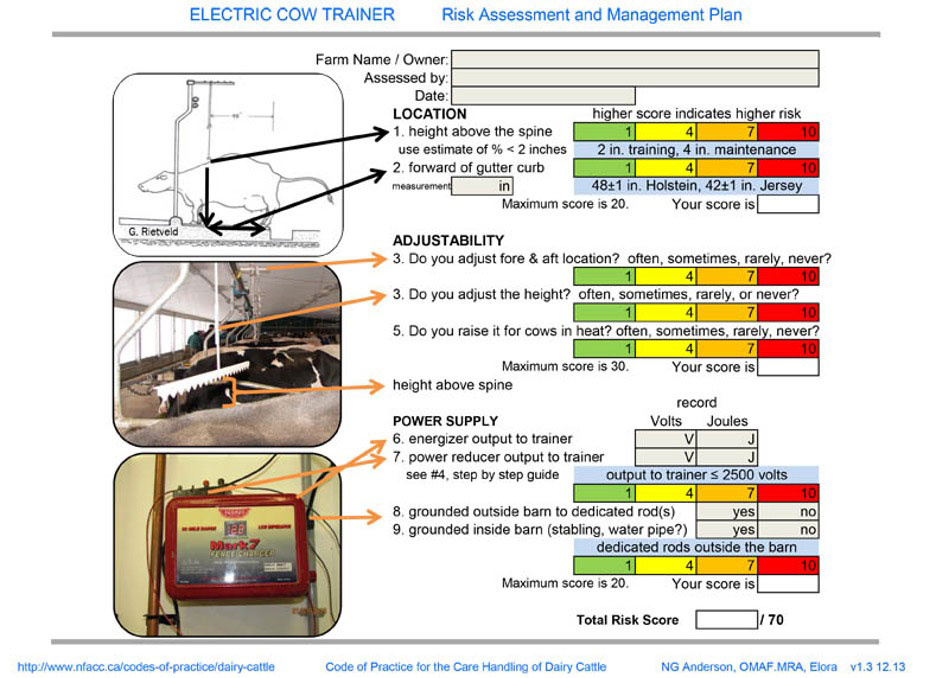

Industry and government guidance on the use of electric trainers in the early 21st c. recommends positioning the trainer from 2 to 4 inches above a cow’s “chine” (or backbone) and advises that the electricity delivered should be of low voltage (around 2500).

The use of electric trainers is dictated by the type of housing used to hold cows used in milk extraction operations. Cows who are chained or tethered by the neck to their stalls move forward to eat and, in the absence of a disciplining device such as the electric trainer, may defecate while they are in this forward position.

In 2022, the percentage of milk operations using a tie-stall system of housing for cows in Canada was just over 70% (excluding operations using robotic milking systems). In the United States, the number of milk operations using tie-stall or stanchion style housing was just under 40% in 2014, trending downward from around 50% seven years earlier in 2007. Data collected on tie-stall operations in the United States in 2007 showed that just over 70% of these operations used electric trainers.

Tie-stall systems are just one form of housing used in cow’s milk extraction operations in North America in the 20th and 21st century. To understand the tie-stall/electric trainer system of housing, and indeed all housing used for cows used in milk extraction operations, we must understand the problem these systems were attempting to solve, all of which emerge from the imperatives of domestic predation. As the writer, M.H. Tse, explained in her work on domestic predation, there are five broad categories of responsibilities or imperatives that a domestic predator must strive to fulfill. While their prey are alive, domestic predators must assume the tasks of feeding, breeding, and sheltering/protecting them, as well as preserving their health and productivity. This includes taking steps to prevent disease or pathogenic contagion from lowering or destroying their productive capacities, and to increase levels of growth (sometimes referred to as “fleshing”) and productivity. The fifth and prime imperative that determines whether these onerous undertakings will be carried out at all is the imperative of extraction, namely, the domestic predator must be able to obtain net returns from their domestic prey that are greater than the costs incurred to keep them alive and producing. Without this prospect there can be no possibility for undertaking the enormous responsibilities of preservation and generation described in the first four imperatives.

For a milk operation to be productive and profitable, a cow’s time should be spent “eating, drinking, milking, or lying down.”[2] To meet the imperative of extraction milk must be extracted from cows three or more times a day. The first design constraint, therefore, is the need to have convenient access to cows and to closely control their activities, and to achieve this objective through the most efficient and economical means. In most cases, this has meant keeping cows indoors in a stationary position and pushing feed in front of their stalls. Keeping cows tethered to small stalls achieves the greatest economy in terms of space requirements, labor costs, and producer convenience. This design allows producers to extract milk from cows, to administer veterinary work, and to inseminate cows in their stalls without having to ever move them. While the tie stall system fulfills the imperative of extraction it gives rise to the defining challenge of all congregation systems: the management of waste. The accumulation of waste that inevitably accompanies the confinement of living prey compromises the imperative of protecting domestic prey from disease and other conditions that might compromise their productive capacities. Waste accumulation may also result in the adulteration of the bodily materials extracted from such animals for human consumption. The electric trainer, then, can be seen as a design solution for preventing udder and foot diseases that may be caused when cows are left to lie in their own waste under conditions of confinement.

In the early 21st century, guidelines from industry organizations began encouraging milk producers to evolve their operations away from the practice of continuous tethering. The National Farm Animal Care Council, for instance, advised in 2023 that producers should stop tethering cows continuously throughout their entire production cycle by the year 2027, and that newly built barns should allow cows “untethered freedom of movement and social interactions year-round.” The Council also advised that tethered cows be allowed “to rest in a head back position” and that electric trainers should be “positioned to enable normal eating, standing, and lying behaviour.”

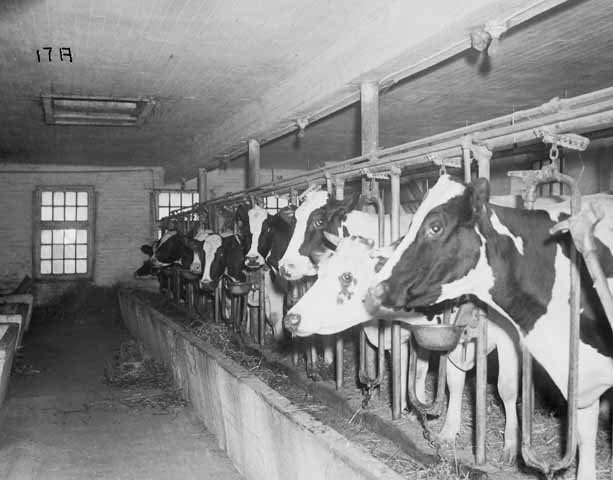

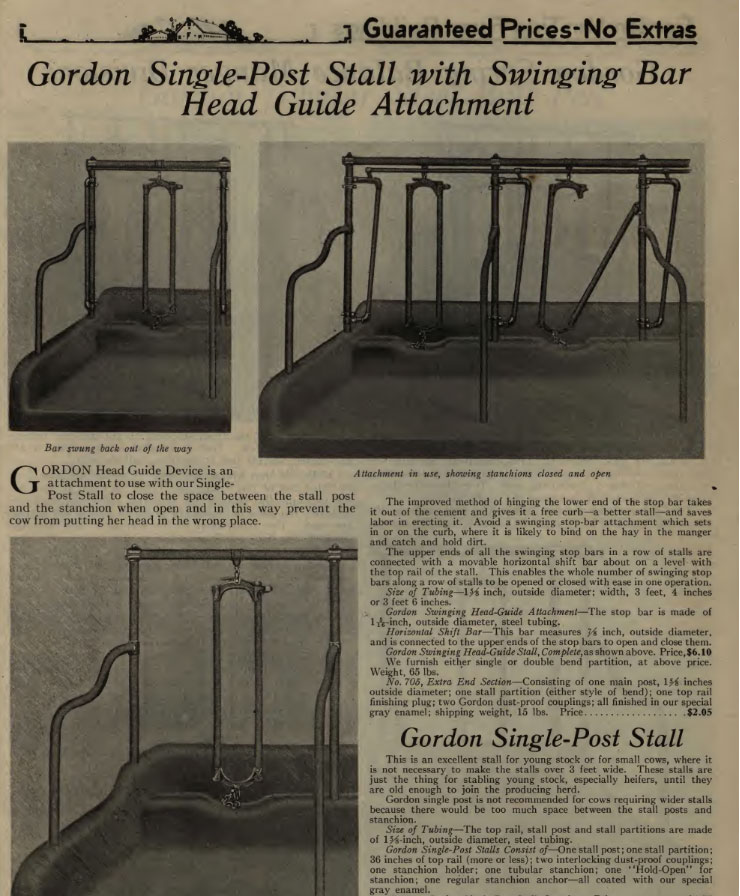

The use of ties or tethers is considered more “humane” than the use of stanchions, which the United States Department of Agriculture defines as restraint of a cow “to an individual stall in a yoke which consists of two rails that close around the cow’s neck after she enters a stall.” Cows closed in a stanchion cannot move their necks and cannot engage in a normal resting position. In the period under discussion, the Farmers Assuring Responsible Management in the United States stopped recommending the use of this type of stanchion stall, and the National Farm Animal Care Council in Canada advised that stanchions were no longer permitted under its guidelines. It should be noted, however, that “headlocking” feed fronts (also referred to as stanchions), which achieve the same kind of immobilization as the “stanchion” stall, did not appear to be affected by these recommendations.

The use of tie-stalls allows for slightly more freedom of neck movement compared to the stanchion, but animal science researchers found that these systems also inhibit “natural behavior, particularly lying behavior,”[3] In a review of the scientific literature on the welfare concerns raised by tie-stall housing, these researchers found “ample evidence that the expression of highly motivated behavioral patterns is impaired in tiestalls.” This includes impairments consisting of “collisions while lying down, lying outside the lying area, duration to reach recumbency, time spent kneeling, unfulfilled intentions to lie down, abnormal lying postures, and lying interruptions.” The ability for cows to lie down is an important indicator of welfare because it has been found to express an “inelastic demand” which causes stress when frustrated.

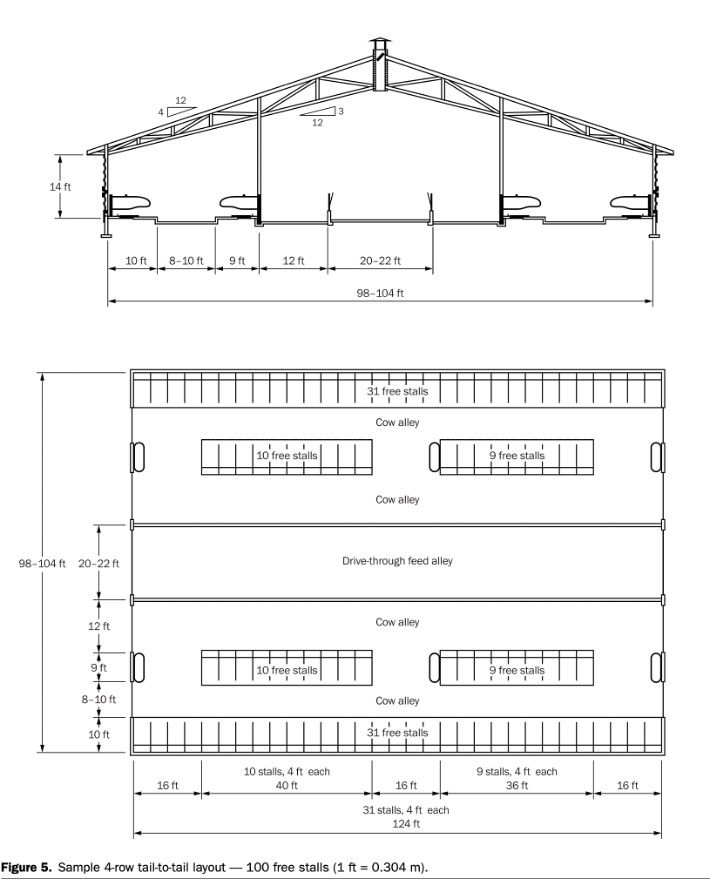

The trend towards what is considered “large” or “very large” milk extraction operations (500 to 5000+ cows) in the United States at the beginning of the 21st century explains the decline in the use of tie-stall housing systems in that period. The need to tie and untie individual cows in a tie-stall system is infeasible in operations holding hundreds or thousands of cows. The number of large operations using tie-stalls as their primary type of housing in the United States in 2014 was only around 1%.

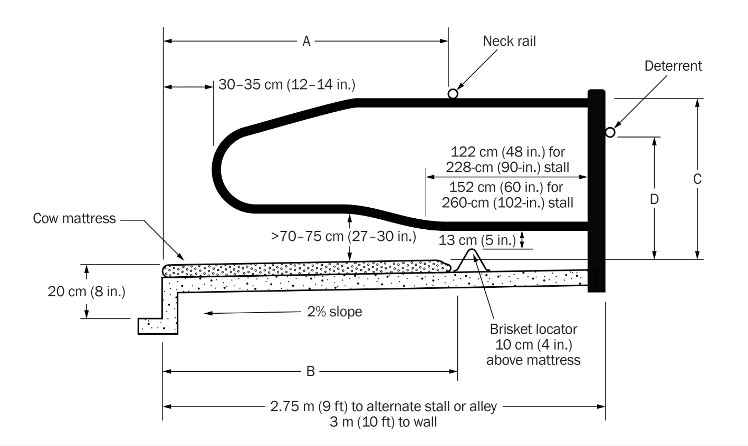

“Loose” or “freestall” housing accomplishes the imperatives of efficiency, feeding, and keeping feed and beds relatively clean through spatial and structural features. For instance, “neck rails” that are mounted horizontally across the stalls in a freestall system are used to achieve positional control over the cows. The neck rail allows a cow to lie in her stall but forces her to move back when standing from a lying position. It also limits how far forward she can stand in the stall.

The United States Department of Agriculture defines a “neck rail” as a pipe or cable “mounted across the top of the freestall loops… designed to discourage cows from moving too far forward when entering the stall and encourage cows to move backward when rising” to “ensure that manure and urine are deposited in the alley way.” Almost all freestall systems utilize neck rails.

Feed in a freestall system is usually deposited in a separate alley that cows cannot walk into. Cows can access feed in the feed alley through a feed line, or feed front, which utilizes rails to prevent cows from entering the feed alley.

The feed line is often equipped with headlocking bars (also known as stanchions). Headlocks are used as a restraint measure to “lock-up” cows when they are eating at the feed line to allow milk producers to perform various interventions such as artificial insemination, pregnancy palpations, and veterinary treatments.

While freestall systems meet the imperatives of confinement, feeding, and waste management without the need for continuous tethering, the move to freestall systems is hindered by cost concerns for smaller producers. The cost comparison between tie-stall systems and alternative “loose” housing systems is affected by the fact that most older milk operations that have been inherited by current producers are tie-stall systems. As animal science researchers, J.M. Bewley et al. report, until the trend towards larger milk operations during the 20th c., tie-stall and stanchion systems served as the primary type of cow housing in the United States. For operations with an existing tie-stall system, the costs of moving to a loose housing system would include the investment required to significantly renovate or construct new barns.

[1] Terry L. Whiting, “Pain in Human and Non-human Animals Caused by Electricity,” Canadian Veterinary Journal 57 (2016).

[2] “Cow Comfort,” Cornell College of Agriculture and Life Sciences, accessed March 28, 2024.

[3] Annabelle Beaver, Daniel M. Weary, and Marina A.G. von Keyserlingk, “Invited Review: The Welfare of Dairy Cattle Housed in Tiestalls Compared to Less-restrictive Housing Types: A Systematic Review,” Journal of Dairy Science 104 (2021): 9383-9417, 9411.